ABM Headless Bridge in Detail

With a completed electric guitar build behind him, Romano Zambon purchased an ABM headless bridge for a future project. Finding little detail available on this bridge system, Romano decided to do some documentation and share both his observations and the plan drawing he drew up.

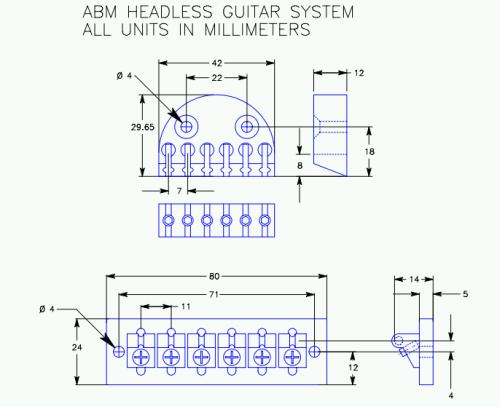

The ABM Bridge Drawing

Overall, his impression was that the “parts seemed to be pretty good quality, I assume they are Brass, they are non magnetic and I doubt they are stainless. The chrome finish seems to be of good quality.” However, it came with no instructions which led him to sit down with a digital caliper and micrometer to arrive at the drawing made available below:

To download the plan, right click on the link and choose to save:

ABM Headless Bridge Drawing – 24 KB

Note: Romano indicated that the drawing was fairly accurate but warned against expecting total accuracy.

Bridge & Tuning Tailpiece

Romano on the bridge and tuner assemblies:

The bridge & tuner seem to only be held down with 2 #6 screws about 1″ long (possibly M4 wood screws). I will most likely use longer stainless screws since they seem a little flimsy.

It appears that they just screw right on top of the body without any routing – certainly makes life easier.

Headpiece

One nice feature Romano documents is the ABM headpiece’s support for conventional guitar strings and double ball end strings.

The headpiece is mounted with 2 #8 (or M6) wood screws. There is an individual allen screw for each string so double ball end strings are NOT required.

Using this headpiece would still require you to use a nut or zero fret. If you wanted to use the head piece with an off the shelf neck it may be a little tricky but not impossible. An alternative may be to use a Floyd Rose style locking nut with a mini headstock. It would certainly be easier to fabricate.

Note: See the Redwood Top Forshage Guitar Revisited for an example of the mini headstock and ABM headless bridge system in action.

Wrap-Up

As with the release of Romano Zambon’s Electric Guitar Plan, it’s his hope that these drawings are helpful to the guitar building community.

Thank you, Romano!

Hey Romano, thanks! This is exactly the type of information a do-it-yourself guitar builder needs to help make design decisions.

Thanks Romano for the ABM headless units plan! Very helpful! I’ve ordered one at ABM’s but they’re not too detailed with regard to installation instructions. A Question about the headpiece: is it mounted 90′ tilted backwards or just ” as you see it” ?

Thanx in advance

Nux

As far as I can tell it should be mounted 90′ degrees tilted backward. However be careful, If you plan on purchasing a neck with a “paddle” headstock (the paddles are typically about 1/2″ ~ 13mm thick) you will need to laminate additional material on the backside and then shape the rear of the headstock to match the contour of the headpiece.

Hope that helps..

RZ

Thanks Romano that helps a lot!

Fortunately I purchased a “log” of birdseye of abt 30 mm thick, so no need to laminate! Although I have finished shaping the neck, I left the “rough” headstock on, now I’m glad I did!

Anyway, thanks for your quick response!

Nux

Gentlemen , we believe this to be the same headstock we’ve used on all our ergo’ Lobster guitars…I think they’re the same ones we’ve purchased them from All Parts for many years …They work incredibly well , easily mount at 90deg. and really increase the sustain in the head area due to their density at the string end… this headstock mated to a rather thick (old school)neck of dense wood (Bocate our Fav’)sustains for days …We use regular tuners on the back of the Lobster so this end just holds the single ball end ..string changes are quick with common strings… We certainly recommend this headstock to potential builders…

I´m building a heaadless guitar with a tailpiece/tuners unit by trying to modify a tremolo unit with fine-tuners. The one thing I can´t quite figure out for sure is how much travel the fine-tuners need in order to tune the guitar to pitch (strings clamped at the head). I tried on a strat copy, and went from slack to pitch in about 5 millimeters. Anybody has a tuning tailpiece to measure this on? Any help would be aprreciated

How does one go about adjusting the intonation? In your picture, I see six philips head screws that look related, but I can’t see a way to move a saddle back and forth.

Thanks,

Gregor

hey folks, I am attempting to build a four string headless bass and i was wondering how i go about ordering some hardware for it. any help would be much appreciated!

thx,

calen

Calen — keep checking back. Within a month I’ll be unleashing a headless tuning system (also for bass) you might find worth waiting for. It will be easy to use, ergonomic, and premium quality.

Let’s stay in touch.